Air Classifier Mill Manufacturer

-

WLM Awtomatikong dahon ng paggiling machine ng gilingan

Ang awtomatikong dahon ng WLM ay nakakagiling makina ng gilingan (air classifier mill) ay isang rebolusyonaryong pang -industriya na gilingan na muling tukuyin ang pagbawas ng l... -

WLM Awtomatikong Paggiling ng Food ACM Machine Factory

Ang WLM Awtomatikong Food Grinding Machine ay gawa sa hindi kinakalawang na asero, maaari itong gumiling ng asukal, asin, pampalasa, bigas, gulay at iba pa ang pangwakas na laki... -

WLM Air Classifier Mill Superfine Grinder Machine

Ang Air Classifier Mill ay isang rebolusyonaryong pang -industriya na gilingan na muling tukuyin ang pagbawas ng laki ng butil at pagproseso ng materyal.Ito ay ang Wanling Compa...

Tungkol sa amin

Karangalan

-

Karangalan

Karangalan -

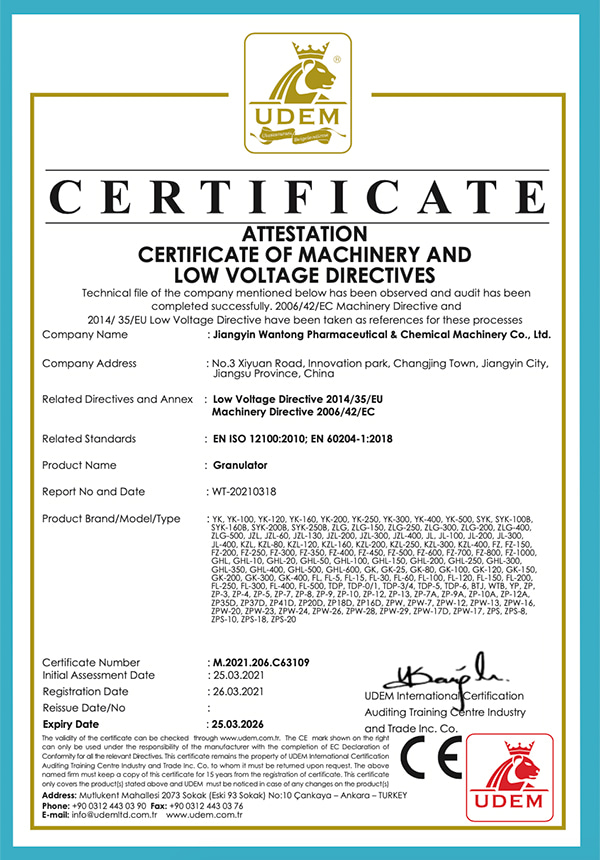

Ce

Ce

Balita

-

Balita sa industriya 2026-01-06

Panimula sa Spice Grinding Machines Mga makinang panggiling para sa pampalasa ay mahahal...

Tingnan pa -

Balita sa industriya 2026-01-04

Panimula sa Industrial Drying Methods Ang pagpapatuyo ay isang kritikal na proseso sa paggawa ...

Tingnan pa -

Balita sa industriya 2025-12-23

Panimula sa Mga Double Cone Blender Ang mga double cone blender ay malawakang ginagamit ...

Tingnan pa -

Balita sa industriya 2025-12-18

Panimula sa Mga Makinang Panggigiling ng Spice Ang mga makinang panggigiling ng pampalas...

Tingnan pa

Pagpapalawak ng kaalaman sa industriya

Can air classifying mills be used for both dry and wet milling processes?

Air classifying mills are typically designed and optimized for dry milling processes. They work by combining impact milling with an integral dynamic classifier, allowing for precise particle size control. The primary mechanism involves using air to convey the material through the mill and to separate finer particles from coarser ones. This process relies heavily on the properties of dry, free-flowing materials.

Key Points on Dry and Wet Milling:

Dry Milling with Air Classifying Mills:

Process: Materials are fed into the mill, where they are subjected to impact and shear forces. The air stream carries the fine particles to the classifier, which sorts and separates them based on size.

Materials: Suitable for a wide range of dry materials, including minerals, chemicals, pharmaceuticals, and food products.

Advantages: Precise particle size control, high efficiency, energy savings, and the ability to handle heat-sensitive materials due to minimal heat generation.

Wet Milling:

Process: Involves the use of liquid (typically water) to aid in the milling process. This can improve particle dispersion, reduce dust, and minimize heat generation.

Applications: Often used for materials that are difficult to mill dry, such as certain pharmaceuticals, pigments, and ceramics.

Equipment: Wet milling typically requires different equipment, such as ball mills, colloid mills, or bead mills, which are designed to handle liquids and create a slurry.

Can Air Classifying Mills be Adapted for Wet Milling?

In general, air classifying mills are not used for wet milling due to the following reasons:

Design Constraints: The design of air classifying mills is inherently suited to handling dry materials. Introducing liquids could lead to clogging, corrosion, and reduced efficiency.

Airflow Dependence: The classification process relies on air to separate particles, which is incompatible with the presence of liquids.

However, certain hybrid systems or modifications could potentially allow for some degree of wet milling, but this is not typical and would require significant redesign and adaptation.

Air classifying mills are best suited for dry milling processes. For wet milling needs, other specialized equipment should be used to achieve the desired results.

How do variations in feed rate and material properties influence the operation of an air classifying mill?

Air classifying mills are versatile tools used for size reduction and particle classification in various industries. Their performance is significantly influenced by the feed rate and the properties of the materials being processed.

Feed Rate

The feed rate in an air classifying mill directly affects both throughput and product quality:

High Feed Rate: While it increases throughput, it can lead to a coarser product due to reduced milling time and potential overloading of the mill. This can also lower efficiency.

Low Feed Rate: Allows for finer particle size and more consistent quality but decreases overall throughput and can be less economical.

Maintaining an optimal feed rate is crucial. Automated systems can help regulate the feed rate to ensure consistent input and enhance both product quality and milling performance.

Material Properties

The properties of the materials being processed also play a critical role:

Hardness and Abrasiveness: Hard materials require more energy to mill and cause higher wear on the equipment, potentially reducing efficiency. In contrast, soft materials are easier to mill, causing less wear and higher efficiency.

Moisture Content: High moisture content can cause clumping and clogging, negatively impacting efficiency and particle size distribution. Low moisture content is ideal for ensuring free flow of material and efficient classification.

Density: High-density materials may need adjustments in airflow and classifier speed for proper classification. Low-density materials are easier to handle but require different settings to prevent fines from being carried away too quickly.

Optimization Strategies

To optimize the operation of an air classifying mill:

Adjust Airflow and Classifier Speed: Tailoring these parameters to match the feed rate and material properties can enhance classification efficiency.

Material Preprocessing: Pre-drying or pre-crushing materials can help manage moisture content and particle size, improving overall milling performance.

Understanding and controlling the feed rate and material properties are essential for optimizing the performance of an air classifying mill. Proper management of these factors ensures efficient operation, consistent product quality, and extended equipment lifespan.